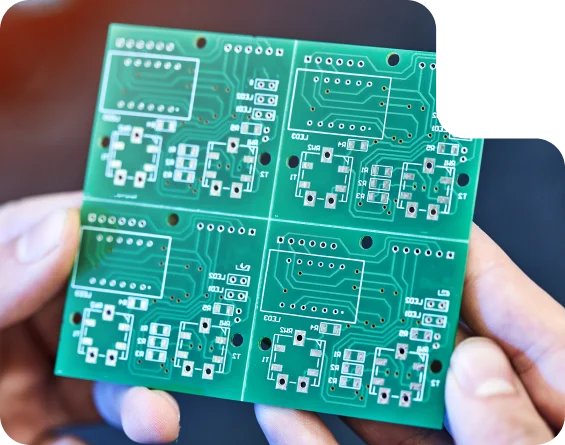

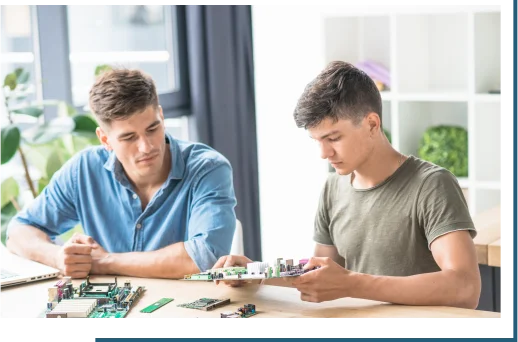

The New Frontier Of Premium PCB Solutions For Your Specific Needs

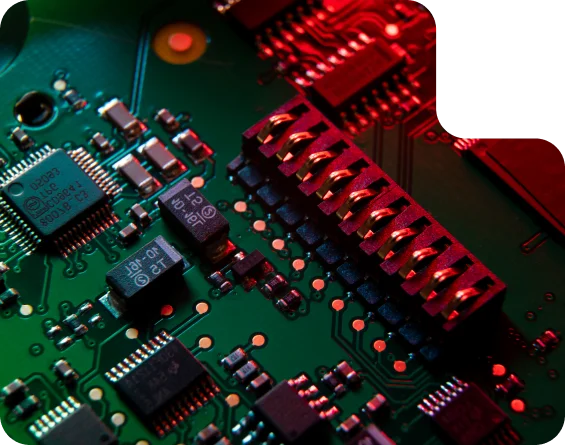

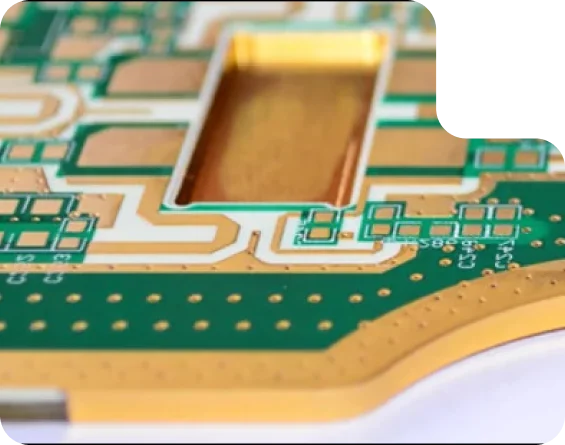

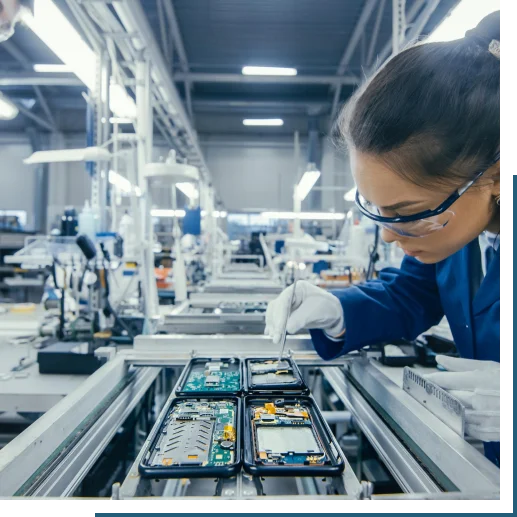

As a pioneer of success in the PCB manufacturing industry, we are adept at leading with a fortitude, which enables us to bring our clients’ ground-breaking visions to fruition through premium PCB fabrication vertical. Leveraging the well-established PCB manufacturing practices and harnessing tech breakthroughs such as Fusion Bonding, etc., we have achieved greater levels of manufacturing efficiency, agility, and collaboration. As one of the best PCB manufacturing companies in USA, we specialize in working side-by-side with the world’s top visionary engineers in the Microwave, RF, Aerospace, Defense, Satellite, Medical and many other industries to deliver solutions, which touch the new frontier of advanced concepts and designs. We have developed an exclusive production line to process EXTRA LARGE PCBs for RF/Microwave industries for PCBs and Antennas. We can process up to 48” x 48” large panels. We can also process 48” x 144” (4 Feet x 12 Feet) EXTRA LARGE SINGLE SIDED PCBs.