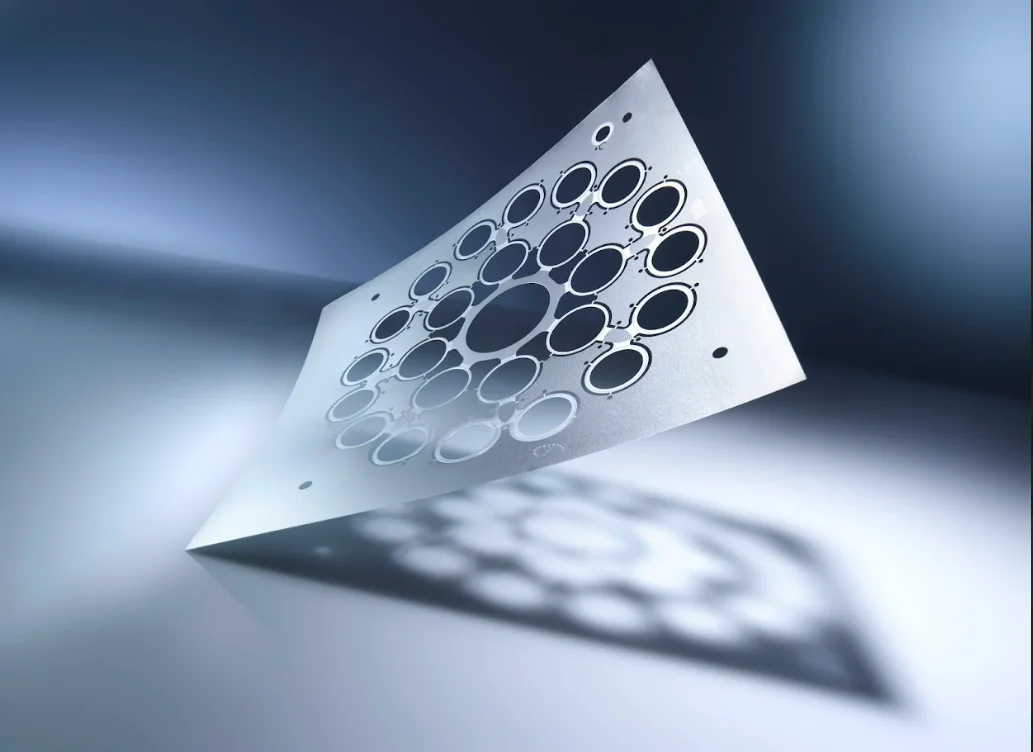

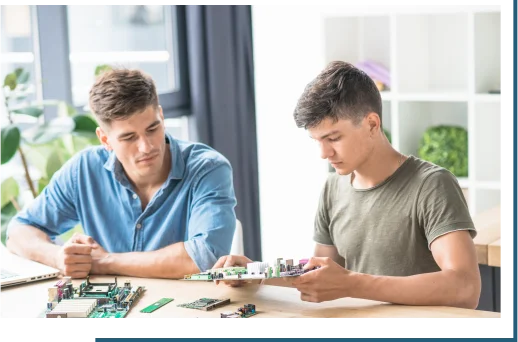

At Transline Technology, we are recognized for the exceptional quality of the wide range of rigid printed circuit boards we manufacture, especially those with Microwave and RF applications. Alongside providing premium metal etching vertical, we have tirelessly pursued excellence in building Flex and Rigid-Flex boards, thus earning accreditation from clients worldwide. As the most trusted metal etching company, we cover partial listing of products and vertical including EMI/RFI Shields, Lead Frames, Heat Sinks, Springs, Heater Elements, Encoder Disks, Medical Devices, Screens/Filters, Stencils/Maks, Encoders, and Washers, Shims & Spacers.

Connect with us now

We are capable of etching metal of different ranges of thickness depending on sheet size, production volumes, metal sturdiness, and the likes.

We deliver exceptional experience for every requirement – be it for large production order, a small prototype run, or a personally developed single piece of art!

We work with companies and manufacturers of all sizes and scales to meet the evolving needs of a large variety of customers

Our experience-led solutions traverse the entire consumer lifecycle and generate value across multiple industries.

Due to acid etching of the metal, no burrs are produced in the metal etching process. And there is no need for using mechanical or heat hard tooling.

Turnaround time is comparatively short because of the process. Simple parts and small volumes can be produced in just 2-5 days. Larger volume or a bit complex part are usually delivered in 2-4 weeks.

As no mechanical force is applied to the metal, the metal etching procedure does not impact the hardness, ductility, or grain structure of metals.

Other procedures generally need extensive mechanical and manual techniques. The metal etching is printed on a very high precision imagesetter that maximizes accuracy and minimizes tooling expenses.

Our metal etching process can keep up with low overall locational as well as dimensional tolerances.

Patterns could be reproduced multiple times on a panel, thereby minimizing the overall expense and ensuring accuracy.

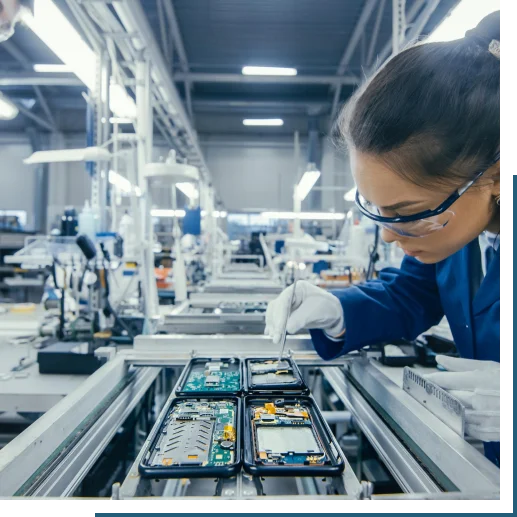

Backed by 30 years of experience under our belt, we have become a leading PCB manufacturing company and a dedicated torchbearer of quality, sincerity, and integrity.

To us, our success is measured by the satisfaction of our clients. It’s only when we can add real value to their needs, shall we feel successful!

Our quality assurance process includes automated optical inspection, rigorous SPC control, metallographic cross section, automated optical inspection, and electrical test facilities to meet our highest quality goals.

We keep ourselves abreast of the technological advancements to deliver next-gen PCB manufacturing solutions that delight clients and inspire loyalty.

Our solutions are competitively priced, which enables us to turn our commitments to “quality in affordability” into achievable milestones.

Harnessing the power of cutting-edge technologies, we can meet even the most complex needs with top-quality RF, Microwave, and mmWavePCB solutions

Thousands of clients have benefited from our solutions. We solve the PCB industry’s biggest challenges.

We’re ready for yours! Have a look at what our clients have to say about us

Find below some of the questions that we are buffeted by most frequently! Get ready to get answers to all your questions.

view all

Harnessing the power of cutting-edge technologies, we can meet even the most complex needs with top-quality RF, Microwave,and mmWavePCB solutions.